Home > Products > Induction furnace > 3000℃ graphitization furnace

1. Application:

The equipment mainly used in the HT heating treatment on carbon material, radiation proof material, carbon nano,carbon fiber, negative electrode materials, graphite powder, Rare earth, rhenium material, pet coke, green coke,contacting terminal material and such related material.

2.Configuration:

380V±5%,50Hz/60Hz 3 phase 5 wire

One control cabinet to one furnace and optional for one to two type or one to four type.

The facility equipped of cooling tower or gas purifier for optional.

3.Technology parameter:

|

Model Parameter |

Lab usage |

Production usage |

||||||||||

|

NTI-SML-54W |

NTI-SML-98W |

NTI-SML-182W |

NTI-SML-400W |

NTI-SML-576W |

NTI-SML-1280W |

|||||||

|

Working size |

mm |

300×300×600 |

350×350×800 |

450×450×900 |

500×500×1600 |

600×600×1600 |

800×800×2000 |

|||||

|

Heating type |

/ |

IF induction heating |

||||||||||

|

Control type |

/ |

Thyristor control or IGBT control ( optional ) |

||||||||||

|

HT zone capacity |

L |

54 |

98 |

182 |

400 |

576 |

1280 |

|||||

|

Loading weight |

g |

HT zone capacity × density (g/cm3)×1000 Remark:1L=1000cm3 |

||||||||||

|

Ultimate vacuum |

Pa |

20 |

||||||||||

|

IF power |

Kw |

150 |

200 |

250 |

400 |

500 |

700 |

|||||

|

Max. working temperature |

℃ |

3000 |

3000 |

3000 |

2900 |

2900 |

2900 |

|||||

|

Usual working temperature |

℃ |

2800 |

2800 |

2800 |

2800 |

2800 |

2800 |

|||||

|

Temperature unifomity |

℃ |

±10 |

±10 |

±10 |

±10 |

±15 |

±15 |

|||||

|

Working environment |

/ |

Vacuum or Argon atmosphere protection( micro positive pressure) |

||||||||||

|

Overall dimension |

mm |

|

|

|

|

|

|

|||||

|

Weight |

Kg |

|

|

|

|

|

|

|||||

You can customize it as per your real requirement.

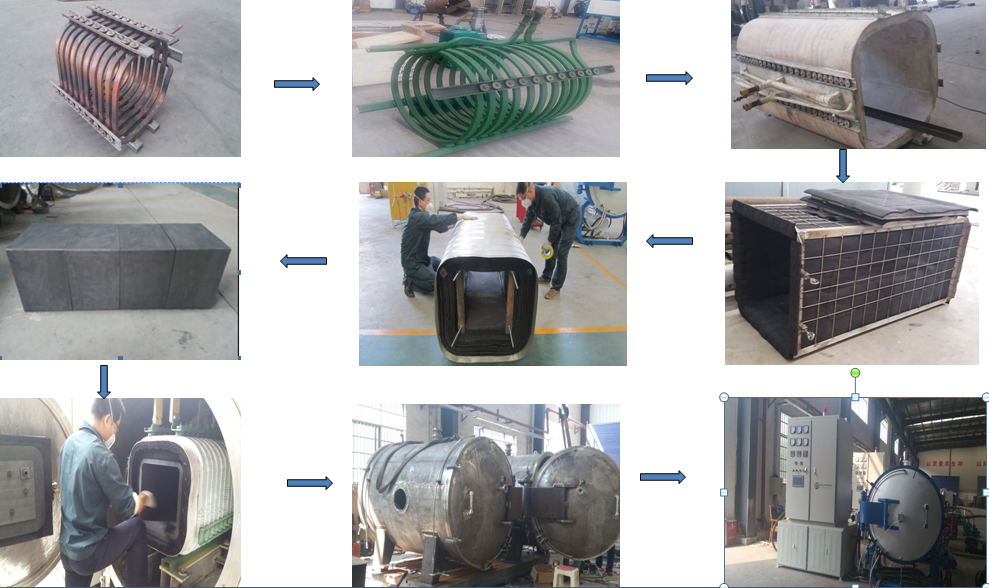

Production procedure

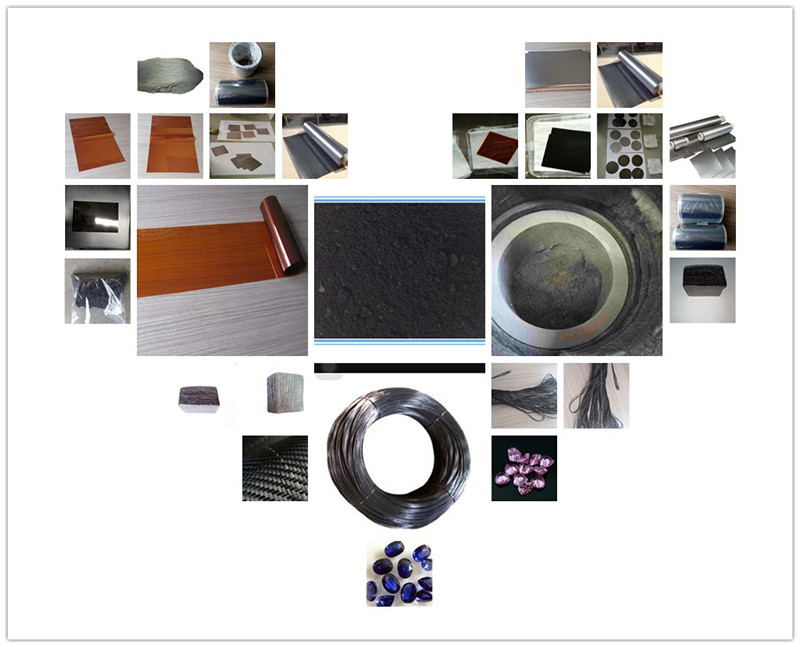

Raw material suitable for heating

Company information

We are real and professional OEM of industry furnace over 10 years who has 10 staff of designer and technican experienced for years,

Main manufacturing products: Graphitization furnace, carbonization furnace, resistance furnace, de-grease furnace, de-rubber furnace, de-wax furnace,laboratory furnace,sintering furnace, melting furnace, quenching equipment, hardening equipment,

anneal equipment and tempering equipment.

IF heating device,ultra audio induction heating equipment,

IF diathermy, hardening, welding equipment,

IF bending pipe machine, cooling tower,

graphite crucible, hard composite carbon felt

and such related industry products.

Clients visit

We have lots of famous clients from the world like Korea, Vietnam, Thailand, Malysia, Russia, Georgia, Ukraine and so on.

Honor of qualification

Packing mode

Service

1.Special size and requirement furnace can be customized.

2.The using method and operation and related knowledge taught by our engineer before shipment.

3.Engineers available to service machinery overseas after-sales service provided.

4.Payment Terms: T/T。

5.Price terms: FOBGuangzhou,China

6.Transport way: by sea, we have good forwarders, super service and price !

7.Delvery time: Estimated time of delivery is 60 days after confirming to receive the deposit payment.

8.1 year of warranty.

9.Other services: we can produce furnace according to your drawing design or requirements.

Better technology, better quality, better price and better service.